|

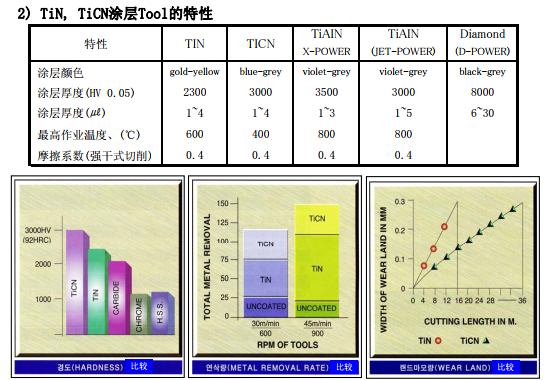

涂层的种类及特性

在工具表面适用涂层可以提高切削效果,提升工具寿命及生产效率.

◇ 涂层的种类

(1) TiN Coating

为了提高涂层效果在工具表面进行Titanium Nitride(TiN)涂层处理.

(2) TiCN Coating

在切削刃上增加力学应力的高强度或在切削软钢时发挥优异的效果

因此在工具表面进行Titanim Carbon Nitride(TiCN)涂层处理.

(3) TiAlN Coating

延续性的高速切削与干式切削一样工具刃上受高的热盈利的情况下能发挥

卓越的效果,在工具表面进行Titanim Alumium Nitride(TiAIN)涂层处理.

(4) AlCrN Coating

受到一般性的加工与极限加工应力的条件下使内磨损性优秀,高温硬度与内产化性

卓越在工具表面进行 Aluminum Chrome Nitride(AlCrN)涂层处理.

(5) X-5070 Coating

(6) Diamond Coating

TiN TiCN TiAlN AlCrN X-5070 Diamond

Coating Coating Coating Coating Coating Coating

|

|

YG EDP NO.COATING&NONE COATING CDDE

|

|

|

TOOL NO.

|

MATERIAL&COATING

|

EDP NO.

|

ETC NO.

|

|

|

NONE

|

M2(SKH51,HSS)

|

E1,D1

|

1

|

|

|

H

|

M2+TiN-COATED

|

E8

|

4

|

|

|

E

|

M2+TiCN-COATED

|

EF

|

6

|

|

|

C

|

M42(SKH59,8%COBALT)

|

E2,D2

|

2

|

|

|

G

|

M42+TiN-COATED

|

E4

|

5

|

|

|

N

|

M42+TiCN-COATED

|

E7

|

7

|

|

|

R

|

M42+FUTURA COATED

|

EQ

|

21

|

|

|

NONE

|

M42+HARDLUBE COATED

|

EU

|

|

|

|

P

|

ASP 30

|

E3

|

10

|

|

|

A

|

ASP 30+TiN-COATED

|

EA

|

11

|

|

|

F

|

ASP 30+TiCN-COATED

|

EB

|

12

|

|

|

Z

|

ASP 30+FUTURA COATED

|

ER,DR

|

|

|

|

Q

|

ASP 60

|

E9

|

13

|

|

|

J

|

ASP 60+TiN-COATED

|

EC

|

14

|

|

|

U

|

ASP 60+TiCN-COATED

|

ED

|

15

|

|

|

O

|

ASP 60+FUTURA COATED

|

EP

|

22

|

|

|

NONE

|

ASP 60+FUTURA COATED(JET-PAWER专用

|

EE

|

|

|

|

M

|

M35(5% COBALT)

|

EL

|

16

|

|

|

V

|

M35+TiN-COATED

|

EN

|

17

|

|

|

W

|

M35+TiCN-COATED

|

EX

|

18

|

|

|

X

|

M35+TiAIN(FUTURA)

|

ET

|

|

|

|

Y

|

T15

|

EK

|

|

|

|

S

|

ASP 2052

|

ES

|

|

|

|

T

|

CATBIDE(K40UF)

|

E5,D5

|

3

|

|

|

T

|

CATBIDE(K44UF)

|

E5,D5

|

19

|

|

|

K

|

CARBIDE+TiN-COATED

|

E6

|

8

|

|

|

D

|

CARBIDE+TiCN-COATED

|

EG

|

9

|

|

|

NONE

|

CARBIDE+X-TREME COATED(X-POWER专用

|

EM

|

20

|

|

|

NONE

|

CARBIDE+FUTURA COATED(JET-POWER专用

|

EH

|

|

|

|

L

|

CARBIDE+X-TREME COATED

|

EM

|

|

|

|

B

|

一 般 CARBIDE+FUTURA COATED

|

EH

|

23

|

|

|

TD

|

CARBIDE+DIAMOND COATED

|

EI

|

25

|

|

|

TH

|

CARBIDE+HARDLUBE COATED

|

EZ,DZ

|

|

|

|

NONE

|

M9V3(CENTER DRILL)

|

EV,DV

|

|

|

|

NONE

|

M9V3+TiCN(CENTER DRILL)

|

EJ,DJ

|

|

|

|

NONE

|

M9V3+TiCN COATED

|

DW

|

|

|

|

NONE

|

M9V3+FUTURA COATED

|

DY

|

|

|

|

NONE

|

M2+HARDLUBE COATED(E/M)

|

G1

|

|

|

|

NONE

|

M2+HARDLUBE COATED(DILL)

|

H1

|

|

|

|

NONE

|

ASP30+HARDLUBE COATED(DRILL)

|

H3

|

|

|

|

NONE

|

碳 C45(DRILL)

|

H2

|

|

|

|

TE

|

WKE45(10%COBALT)(E/M)

|

G2

|

|

|

|

NONE

|

CARBIDE+FUTURA TOP(DRILL)

|

H4

|

|

|

|

NONE

|

M35+HARDLUBE(DRILL)

|

H5

|

|

|

|

TA

|

T1(E/M)

|

G3

|

|

|

|

NONE

|

ASP30+TiN-CrN(DRILL)

|

H6

|

|

|

|

TX

|

CARBIDE+X-CEED(E/M)

|

G4

|

|

|

|

TC

|

HSS+TiAICN(E/M)

|

G5

|

|

|

|

NONE

|

WKE45(10%COBALT)(CUTTER)

|

N2

|

|

|

|

NONE

|

CARBIDE+SUPERMITRIDE COATING(E/M)

|

G6

|

|

|

|

NONE

|

CARBIDE+CNi COATED(E/M)

|

G7

|

CROVGA

|

|

|

NONE

|

CARBIDE+X-5070 COATED(E/M)

|

G8

|

|

|

|

TG

|

CARBIDE+MULTI-1 COATED(E/M)

|

G9

|

26

|

|

|

YG

|

YPM+MULTI-1 COATED(E/M)

|

GA

|

|

|

|

CG

|

M42+MULTI-1 COATED(E/M)

|

GB

|

|

|

|

Multi-1 Coating=ALCRONA Coating

|

|